|

| |

在傳統高壓接頭產品型錄內包含多選擇性的高壓接頭及纜線, 從產品的種類可以知道Reynolds Industries對傳統產品在工程, 品質和客戶服務方面的承諾. Reynolds領導高壓接頭工業所設計的高壓接頭可在高度70,000呎, 工作溫度 -55°C至+125°C. 並非型錄內所有產品均設計適用上述極端的工作環境, 但是產品都能使用於所定義的規格. Reynolds先進產品部門生產多接點高壓接頭, 這個部門的技術是非常先進的, 多接點高壓接頭代表高科技的設計生產技術. | Description

The Legacy Group of connectors contained in this catalog provide a wide selection of multi-pin high voltage connectors and cable assemblies. These products reflect the legacy of Reynolds Industries strong commitment to engineering, quality and customer service.

Reynolds leads the connector industry in the design of high voltage connectors capable of operating at altitudes up to 70,000 feet while exposed to temperatures as low as -55°C and up to +125°C. Not all products shown in this catalog are designed to operate at these extremes, but all will perform with a high degree of reliability when operated as specified.

Reynolds also manufactures multi-pin connectors within its Advanced Group of connectors. Technologically advanced, these connectors represent the state-of-the art in high voltage connector manufacture.

|

Hi-Rel Multi-pin Connectors for Military/Aerospace Applications 軍事或航太使用的高可靠度多接點高壓接頭

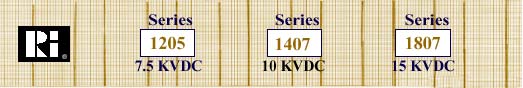

| Series 1205

5 pin series in production since 1970. Ideally suited for low power TWTs and TWT power supplies. Rated at 7.5 KVDC at any altitude up to 70,000 feet. 該系列為5個接點端子高壓接頭從1970年開始量產,適用於低功率行波調束管(TWT)或行波調束管電源供應器. 該系列高壓接頭在高度70,000呎工作時耐壓達7.5KVDC |  | 7.5 KVDC Rated | Series 1407

7 pin series rated at 10 KVDC at any altitude up to 70,000 feet. Widely used on TWTs and TWT power supplies. 該系列為7個接點端子高壓接頭廣泛適用於行波調束管(TWT)或行波調束管電源供應器. 該系列高壓接頭在高度70,000呎工作時耐壓達10KVDC |  | 10 KVDC Rated | Series 1807 (bayonet coupling)

7 pin series rated at 15 KVDC at any altitude up to 70,000 feet. Ideal for higher power TWTs and Radar power supplies. 1807系列(快速耦合接頭) 該系列為7個接點端子高壓接頭適用於高功率行波調束管(TWT)或行波調束管電源供應器. 該系列高壓接頭在高度70,000呎工作時耐壓達15KVDC |  | 15 KVDC Rated | Series 1807 (threaded coupling)

A threaded version of the 1807 bayonet coupled series 1807系列(旋轉耦合接頭) 此系列是旋轉耦合式接頭 |  | 15 KVDC Rated | Series 403 (bayonet coupling)

Ruggedized connectors rated at 35 KVDC for operation from sea level to 70,000 feet. Stainless steel coupling ring and body. 403系列(快速耦合接頭) 該系列強固型接頭在高度70,000呎工作時耐壓達35KVDC |  | 35 KVDC Rated | Multi-pin Connectors for Limited Military/Aerospace Applications 軍事或航太使用的多接點高壓接頭

| RMC Connector Series

A series of high voltage multi-pin connectors for use in applications where altitude requirements do not exceed 15,000 feet and the operating temperature is in a range of -40°C to +85°C. Inserts are available from a single contact to 21 contacts. Voltage ratings are from 5 KVDC to 45 KVDC RMC接頭系列 該系列多接點高壓接頭使用在高度未超過15,000呎及工作溫度範圍在-40°C至+85°C. 接頭內最少可插入一個接點端子最多可插入達21個接點端子,耐電壓為5 KVDC至45 KVDC |  | 5 - 45 KVDC Rated |

| Cable preparation and assembly instructions: 1205 1407 1807 RMC Series

Bulk cable specifications and ordering

AWG wire data

Application guide for product selection

Paschen curve: Voltage arc level vs atmospheric pressure

Index by part number |

General Specifications

| | 1205 | 1407 | 1807 | Sea Level Voltage Rating (KVDC) | 7.5 | 10 | 15 | 70,000 foot Altitude Rating (KVDC) | 7.5 | 10 | 15 | Bayonet Coupling | Yes | Yes | Yes | Threaded Coupling | No | No | Yes | Bayonet Ring Diameter (inches/mm) | 1.01/25.6 | 1.14/28.9 | 1.37/34.7 | Insulator Material (Plug) | Sil. Rubber | Sil. Rubber | Sil.Rubber | Insulator Material (Receptacle) | Sil. Rubber** | Sil. Rubber** | DAP* | Coupling and Body Material/finish | Alum./nickel | Alum./nickel | Alum./nickel | Bayonet Coupling Finish/lubricant | Nickel/dry lube | Nickel/dry lube | Nickel/dry lube | Male Contact Diameter (inches/mm) | 0.040/1.01 | 0.052/1.32 | 0.060/1.52 | Male Contact Material/finish | Brass/gold | Brass/gold | Brass/gold | Female Contact Material/finish | BeCu/gold | BeCu/gold | BeCu/gold | Hooded Female Contact | Yes | Yes | Yes | Front and Rear Mount Receptacles Available | Yes | Yes | Yes | Uses FEP Wire or Type ‘L’ Cable | Yes | Yes | Yes | 100% test voltage @ 70,000 feet simulated and at ambient temperature | 10 KVDC | 15 KVDC | 22.5 KVDC |

Download this page as a PDF for best print quality.

Series 403

Ruggedized 3 pin connectors designed to operate at

35 KVDC from sea level to 70,000 feet. Operating

temperature is -55°C to +125°C.

| .jpeg) .jpeg) | Applications

Series 403 connectors feature stainless steel bodies and coupling rings and are resistant to salt spray and other corrosive environments. The connectors are uniquely qualified to function aboard ships or airborne Radar applications. The connectors and cable assemblies are 100% tested at 50 KVDC at a simulated altitude of 70,000 feet. (ambient room temperature)

|

General Specifications

| | Voltage Rating (KVDC) | 35 | | Operating Temperature | -55°C to +125°C. | | Plug Insulator Material | Diallyl Phthalate Plastic | | Receptacle insulator material | Diallyl Phthalate Plastic | | Coupling type | Bayonet

| | Bayonet coupling ring diameter. Inches/mm | 2.10/53.3 | | Body and coupling ring material/finish | Stainless/Passivation | | Male Contact Size (Plug) | 12 gauge | | Male Contact Material/Finish | Brass/Gold | | Female Contact Material/Finish | BeCu/Gold | | Hooded Female Contact | Yes | | Crimp Braid Termination (plug) | Yes | Maximum operating current (RMS) | 13 amps | 100% test voltage | 50 KVDC @ 70,000 feet simulated. Ambient room temperature |

Download this page as a PDF for best print quality.  | .gif)

MULTI-CONTACT

HIGH VOLTAGE CONNECTOR KITS

and CABLE ASSEMBLIES FEATURES: -40º to +85º C temperature Can be assembled in the field Materials conform to Mil-Specs Highly reliable Sea level to 15,000 ft operation Environmentally sealed interface

| .gif)

| *Reynolds Industries, Inc. acquired the RMC connector series product line from Rowe Industries, Inc. in 1997. |

Download this page as a PDF for best print quality.

Reynolds先進高壓接頭, 這些接頭是Reynolds Industries依據過去40年生產高壓接頭和應用高壓系統接頭所發展出的新技術.

在航太工業的高壓接頭使用者一直在尋求一種能減少大氣壓力的微型高壓接頭, 工作溫度-55°至+125° C同時可降低電暈到可接受範圍的微型高壓接頭.

Reynolds系列先進高壓接頭介面密封設計是透過使用非常小而又有彈性介面的密封裝置來滿足使用者的要求.

小的接頭需要配合更小的高壓線, Reynolds公司同時間開發小直徑的電線和電纜來配合微小接頭的介面密封設計.

除此之外, 一種在電線上塗膠增加使用裝備上介電附著力的技術被開發出來. 最後, 高壓衰減電線或”線損”產品被開發出來, 進一步補足了先進高壓接頭系列產品

|

Technical Discussion | | A discussion centered around the Advanced interface sealing system and the Advanced group of connectors. A brief history of the evolution in the design of high voltage connectors is presented. |

JR Series 該系列接頭和電纜產品可在高度70,000呎6 KVDC -55 to +125° C.環境下工作 | | A junior version of the Pee-Wee series of high voltage connectors and cable assemblies. Although micro-miniature in size, this series of connectors and cable assemblies will operate at voltages up to 6 KVDC at 70,000 feet altitude over a temperature range of -55 to +125° C. |

Pee-Wee Series 該系列適用於航空及軍事工業 接頭和電纜產品可在高度70,000呎12 KVDC -55 to +125° C.環境下工作 提供單一接點或多接點產品 陶瓷 接頭座可應用在密封環境下 | | A series of subminiature high voltage connectors and cable assemblies for the Aerospace/Defense Industry. These connectors will operate at voltages up to 12 KVDC at 70,000 feet altitude over a temperature range of -55 to +125° C. Single and multi-pin versions are available. Ceramic receptacles are also available for applications where a hermetic seal is required. |

Magnum Series 該系列是多點高壓接頭和電纜產品 這種產品可應用在很多的產品設計 因為此系列產品是將測試過的料件成為一體成型 包覆完整的電纜組 Magnum系列接頭為不鏽鋼材質 特殊偶合環 產品可應用在密封環境下 | | Magnum is a series of quality directed, multi-pin high voltage connectors and cable assemblies. These connectors provide a large number of design solutions because they are a mechanically built-up assembly of pre-tested piece parts, as contrasted to a one piece, encapsulated, molded-in-place cable assembly. The Magnum series features stainless steel shells, a unique bayonet coupling and a range of receptacles that includes a hermetic ceramic version. |

Magnum+Plus Series | | This series is the same as the Magnum series with the exception that 3 of the 6 pins have slightly larger seals which enables the 3 larger pins to be rated at 14 KVDC. |

Century Series | | This series of single pin connectors and cable assemblies is slightly larger than the Pee-Wee series, has a higher voltage rating and is more rugged. The receptacles are available in both plastic and high alumina ceramic versions. |

Century+Plus Series | | A slightly larger version of the Century series with a higher voltage rating. |

Maxxum Series | | These connectors and cable assemblies have the second highest voltage rating of any of the Advanced group of connectors. They are mainly used on ECM and Radar systems to connect the collector element of high power TWT’s to a high voltage power supply. Ceramic receptacles are available for applications requiring a hermetic seal. |

Max Series | | A series of anode lead assemblies and receptacles designed specifically to interconnect cathode ray tube anodes to high voltage power supplies in airborne avionics suites of both military and commercial aircraft. |

Avvion Series | | A series of multi-pin cable assemblies that permit easy mating & unmating to the gun end of a cathode ray tube without potting or encapsulation. The connector interface provides high voltage sealing for the focus element and low voltage pins for the elements typical of the cathode, grid and heater. Designed for the avionics suites of high performance military and commercial aircraft. |

Download this page as a PDF for best print quality.  | AWG | STRANDING | APPROX. DIA. | CROSS SECTION | DC RESISTANCE | CURRENT RATING | | | MM | INCHES | MM2 | OHMS/1000M | (amps) Free air. 80°C* |

| | 30 | 41/46 | 0.30 | .012 | 0.051 | 337.3 | 0.40 | | 29 | 51/46 | 0.35 | .014 | 0.064 | 271.3 | 0.50 | | 28 | 41/44 | 0.37 | .015 | 0.081 | 212.3 | 0.60 | | 26 | SOLID | 0.40 | .016 | 0.130 | 133.9 | 1.0 | | 26 | 7/34 | 0.48 | .019 | 0.141 | 122.4 | 1.0 | | 26 | 10/36 | 0.51 | .020 | 0.127 | 136.2 | 1.0 | | 26 | 19/38 | 0.50 | .020 | 0.151 | 113.8 | 1.0 | | 26 | 51/42 | 0.56 | .022 | 0.160 | 107.3 | 1.0 | | 26 | 66/44 | 0.48 | .019 | 0.131 | 131.9 | 1.0 | | 24 | SOLID | 0.51 | .020 | 0.205 | 84.3 | 1.6 | | 24 | 7/32 | 0.61 | .024 | 0.224 | 76.8 | 1.6 | | 24 | 10/34 | 0.64 | .025 | 0.201 | 85.6 | 1.6 | | 24 | 16/36 | 0.61 | .024 | 0.203 | 85.0 | 1.6 | | 24 | 19/36 | 0.64 | .025 | 0.241 | 71.5 | 1.6 | | 24 | 41/40 | 0.59 | .023 | 0.205 | 84.0 | 1.6 | | 22 | SOLID | 0.64 | .025 | 0.326 | 52.8 | 2.5 | | 22 | 7/30 | 0.76 | .030 | 0.356 | 48.2 | 2.5 | | 22 | 19/34 | 0.80 | .032 | 0.383 | 44.9 | 2.5 | | 22 | 26/36 | 0.75 | .030 | 0.329 | 52.5 | 2.5 | | 22 | 65/40 | 0.78 | .031 | 0.326 | 52.5 | 2.5 | | 20 | SOLID | 0.81 | .032 | 0.518 | 33.5 | 4.0 | | 20 | 7/28 | 0.96 | .038 | 0.567 | 30.5 | 4.0 | | 20 | 10/30 | 1.02 | .040 | 0.509 | 33.8 | 4.0 | | 20 | 19/32 | 1.01 | .040 | 0.609 | 28.2 | 4.0 | | 20 | 26/34 | 0.94 | .037 | 0.524 | 32.8 | 4.0 | | 20 | 105/40 | 0.99 | .039 | 0.526 | 32.8 | 4.0 | | 18 | SOLID | 1.02 | .040 | 0.823 | 21.0 | 8.0 | | 18 | 7/26 | 1.21 | .048 | 0.901 | 19.0 | 8.0 | | 18 | 16/30 | 1.23 | .048 | 0.815 | 21.0 | 8.0 | | 18 | 19/30 | 1.27 | .050 | 0.968 | 17.7 | 8.0 | | 18 | 41/34 | 1.19 | .047 | 0.826 | 21.0 | 8.0 | | 18 | 65/36 | 1.25 | .049 | 0.823 | 21.0 | 8.0 | | 18 | 168/40 | 1.34 | .053 | 0.842 | 20.3 | 8.0 | | 16 | SOLID | 1.29 | .051 | 1.309 | 13.1 | 10.0 | | 16 | 7/24 | 1.53 | .060 | 1.433 | 12.1 | 10.0 | | 16 | 19/29 | 1.43 | .056 | 1.220 | 14.1 | 10.0 | | 16 | 26/30 | 1.50 | .059 | 1.324 | 13.1 | 10.0 | | 16 | 41/32 | 1.50 | .059 | 1.326 | 13.3 | 10.0 | | 16 | 65/34 | 1.57 | .062 | 1.309 | 13.1 | 10.0 | | 16 | 260/40 | 1.73 | .068 | 1.303 | 13.1 | 10.0 | | 14 | SOLID | 1.63 | .064 | 2.081 | 8.2 | 15.0 | | 14 | 7/22 | 1.85 | .073 | 2.285 | 7.6 | 15.0 | | 14 | 19/27 | 1.80 | .071 | 1.940 | 8.9 | 15.0 | | 14 | 41/30 | 1.89 | .075 | 2.088 | 8.2 | 15.0 | | 12 | 7/20 | 2.44 | .096 | 3.660 | 4.9 | 20.0 | | 12 | 19/25 | 2.27 | .090 | 3.085 | 5.6 | 20.0 |

Download this page as a PDF for best print quality.

Background

Selection of the best high voltage connector for a given application is important not only for reliable performance but also cost. This guide will assist the user in making the best match between system requirements and Reynolds high voltage connectors, cable assemblies and cable.

| Voltage Rating | Reynolds rates voltage as the “maximum operating voltage.” Ratings are for steady state DC. The user should define the maximum DC voltage of the proposed circuit and select a connector rated at least 25% above the maximum circuit operating voltage. If the circuit contains voltage with an AC component or is pulsed DC, the user should consult with Reynolds engineering department before choosing a connector.

| Altitude Operation | If a proposed application involves operation at a reduced pressure equivalent to 15,000 feet or higher, the user should refer to Paschen's Curve for background on the relationship of voltage stand off and atmospheric pressure. Connectors presented in this catalog are clearly rated concerning operation at altitude. Reynolds altitude rated connectors use precision elastomeric seals

to effect an altitude seal and requires no silicone grease to operate reliably at their rated voltage. | Operating Temperature | The user should accurately establish the operating temperature range of any application for high voltage connectors. This

is very important for sea level applications and becomes critical for altitude operation. The user should be realistic in evaluating the temperature range. Connectors designed to operate over a range of -55°C to +125°C are considerably more expensive than those designed for room ambient operation or even -40°C to +70°C. The operating temperature is clearly indicated for all connectors in this catalog. | | Plugs | Plugs, ends that are attached to cable assemblies, are available in some cases as a bag assembly for installation by the user. Reynolds generally discourages the purchase and installation of these connectors by the user especially if the final

assembly is to be used at altitude and/or extremely cold temperature, for several reasons. (1) Extreme cleanliness must be

observed to preclude conductive contamination. (2) If the connector requires bonding (most do) only an experienced person with all the necessary potting room equipment should attempt the installation. (3) Assemblies must be voltage stress tested and, when destined for use at altitude, in an altitude chamber capable of simulating the equivalent of 70,000 feet.

| | Receptacles | Receptacles also must be kept clean, particularly in the interface area. If the rear portion of the receptacle requires encapsulation, it is best to have this done and tested by Reynolds prior to shipment. However, the potting of a receptacle

is usually straightforward and can be accomplished by following the material manufacturer’s printed instructions. | | Wire and Cable | There is no single wire or cable suitable for all applications and conditions. Following are comparisons:

| FEP | Silicone Rubber | | Advantages: | Advantages: | | High dielectric | Fair dielectric strength | | Abrasion resistant | Good flexibility | | Good corona characteristics | Easy to bond and encapsulate with silicone rubber | | Can be etched and silicone rubber coated | Disadvantages: | | Resistant to most fluids including Coolanol™ | • Relatively large diameter compared to FEP | | Disadvantages: | • Susceptible to pinholes and wire migration | | • Must be etched for bonding or encapsulation | • Incompatible with Coolanol™ and some other oil dielectrics |

| FEP Wire & Cable

Etching- Coating | FEP cable can be etched and coated with silicone rubber for encapsulation using silicone rubber compounds or bonding to molded silicone rubber components using approved elastomeric bonding materials. FEP wire that has been etched but not coated can also be used for encapsulation or bonding to most epoxy materials. These processes give FEP wire a versatility found in no other high voltage wire or cable and make it an excellent choice for most high voltage applications. | | Cable Routing and Bend Radius | In routing cable, the user should take care to avoid making sharp bends. Sharp bends put added stress on the wire strands and can create a corona stress point. Sharp or rough metal edges in the routing area should also be eliminated especially when using silicone cable. Torquing a cable excessively during routing should be avoided. | | Liquid Dielectrics | Reynolds connectors use silicone rubber seals and “O” rings to effect dielectric and pressure sealing. Silicone rubber, including silicone rubber cable, is incompatible with many dielectric oils and Coolanol™ dielectric. While these are excellent dielectric mediums they can cause silicone rubber to swell. Some Reynolds connectors offer fluorsilicone seals and/or insulators for use with these dielectrics. Only FEP or PFA cable should be used where these dielectrics are present. | | Loss Line Cable | Reynolds manufactures a complete line of high voltage loss line or distributed loss R.F. attenuation cable. The user requiring R.F. attenuation should consider using loss line. Reynolds engineers are available for application consultation. | | Corona | Users with concerns about corona should consult Reynolds engineering department before making a high voltage connector choice. Reynolds is extremely knowledgeable concerning the origins of corona, its effects and possible remedies. Reynolds makes no claim to manufacturing “corona free” connectors, cable or cable assemblies. Reynolds does, however, maintain extensive corona research and test data on its products with the objective of manufacturing connectors as resistant to the effects of corona as possible. Reynolds is noted in the industry for its corona detection equipment and technical competence to analyze the existence and level of corona in a connector or circuit. |

Download this page as a PDF for best print quality.

.gif) | Paschen’s results

In the 19th century, Paschen, a German scientist, conducted experiments to determine electrical arc char-acteristics when ambient pressure changed. He spaced two spherical electrodes at a constant 3/8 inch (1cm). He then reduced the ambient pressure in increments from sea level (760 mm Hg.) to 260,000 ft. (0.01 mmHg.). At each selected pressure increment he increased the voltage across the electrodes until a low-energy arc occurred.

The curve on the chart above tells the story. At sea level, about 30,000 VDC is required to initiate an arc across the electrode gap. At 47,000 ft. the arc level drops to about 1200 VDC. Accordingly, the worst altitude is 150,000 ft., where only about 300 VDC will arc across the electrodes. Electronic Countermeasure Systems (ECM) and other radar and electronic systems aboard aircraft require high voltage connectors and cable assemblies to function at altitudes up to 70,000 ft. with 1,500 to 40,000 volts applied. Missile-borne ECM systems raise the requirement to 150,000 ft..

The problem

In low voltage electrical connector applications (less than 500 volts DC), reduced air pressure presents little concern or special design considerations. But to take one example, a high voltage connector operating requirement of 10,000 volts DC, the creep path (arc distance) between two conductors at sea level would be 1/2 inch (12.7mm), and at 70,000 ft. it would be 5 inches (127mm) minimum.

The extended creep path solution

If no design solution were possible other than the lengthening of the creep path, then aerospace high voltage connectors would occupy unreasonable volume and would be extremely heavy.

Elastomer seals

To eliminate the need for a lengthened creep path, all connectors manufactured by Reynolds that are rated for altitude operation have precision elastomer seals incorporated into the design. These seals block high voltage creep at reduced air pressure.

Temperature swing effect

Temperature swings from -55°C to +125°C can cause elastomer materials to exhibit compression set or loss of memory between hot and cold cycles. This can result in voltage creep past the seals and subsequent failure of the connector. Through the use of select elastomer materials and seal geometry, Reynolds altitude rated connectors will operate reliably when exposed to reduced pressure and hot and cold cycling.

|

Download this page as a PDF for best print quality. |